Outotec Oyj is a Finnish high technology company that specializes in designing and developing tailored process machinery solutions and life cycle services for mining, metal, energy and water industries. With 4800 employees, operations in 25 countries, and business in 80, the company is known for innovative products and solutions that create value for the customer from natural resources in the most sustainable way.

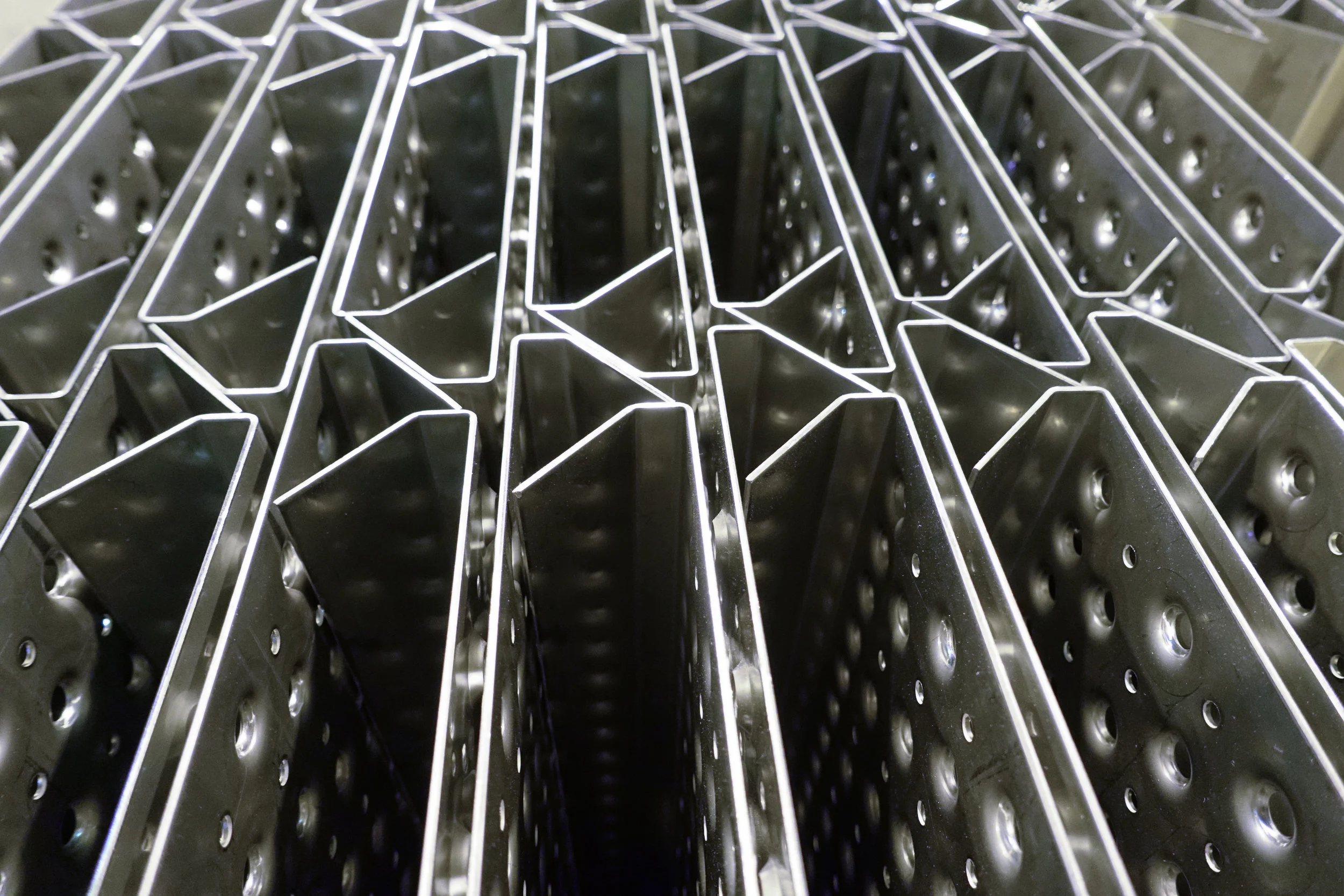

Out of Outotec’s five production facilities, Outotec Turula Oy is the largest factory with 200 employees and 25,000 m² premises located in Outokumpu, Finland. The Turula engineering workshop produces equipment for metallurgical processes, mainly copper production. The company has always invested in the latest technologies to ensure a seamless production process.

Quality is critical for our customers, because they often employ our products in very harsh environments where a defect can have very costly consequences. Thus, our ability to prove quality in accordance with EN ISO 3834 is a clear competitive advantage.Markus MutanenPlant Manager, Outotec

Main challenge

Premekon is renowned for its high-quality products, which combine its solid experience in manufacturing metal structures and the utilization of state-of-the-art technology in both design and production processes. Production quality control is of key importance as the manufacture of walkways must comply with the EN ISO 14122 standard, which is also a prerequisite for customer purchases. In order to meet the standard requirements, Premekon was looking for a customizable software solution that would make production monitoring more convenient, integrate with its current welding fleet, and suit the needs of an SME.

The WeldEye Solution

Outotec has developed its partnership with Kemppi by deploying different modules of WeldEye welding management software in phases. In 2012, Kemppi provided the Turula workshop with a quality control module as a concrete way to verify welding quality. With increasing demands on quality assurance from customers worldwide, the software’s ability to produce qualitative data and reports on welding quality was seen as a clear competitive advantage. In addition, it was now easy for Outotec to demonstrate welding production compliance with the requirements of the EN ISO 3834-2 quality standard in regular auditing procedures.

In 2014, Outotec Turula upgraded to the complete welding management software solution, which covered all aspects of the workshop’s welding operations. Not only was it now possible to control and verify top-level welding quality, but also make WPS and welder qualifications management more efficient, and have the complete project documentation ready in just a few minutes.

With positive experiences and proven benefits of use, Outotec is now considering extending the software solution to its other production facilities and subcontractors. As a modern, cloud-based solution, WeldEye is a perfect fit for a globally operating company such as Outotec with the need for a multisite welding management solution.