WeldEye ArcVision

Gain insight into arc-on time and welding parameters.

Gain insight into arc-on time and welding parameters

WeldEye ArcVision makes welding production monitoring more effortless than ever without requiring additional devices. It is an integrated Industry 4.0 solution that cost-efficiently and constantly tracks and records arc-on time and welding parameters for better insight into welding production.

Raw data is collected digitally from connected welding stations and uploaded wirelessly to the WeldEye ArcVision module. The data is then visualized into clear tables and graphs that can be filtered based on different needs and viewed conveniently from your laptop’s web browser.

Even a simple solution for monitoring welding productivity can significantly benefit most companies and improve workflow planning in welding production, not to mention recognizing savings in material costs and increasing valuable arc-on time.

Clear visuals

Cloud-based solution

Do you know how your welding machines are being used?

WeldEye ArcVision collects data automatically from all connected welding stations without additional actions from machine users:

• Arc-on time per hour, day, week, or month

• Wire feed speed

• Welding parameters (A; V)

• Filler wire usage (kg)

• Energy consumption (kWh)

• Estimated gas consumption

• Welding machine details

Do you know how your welding machines are being used?

WeldEye ArcVision collects data automatically from all connected welding stations without additional actions from machine users:

• Arc-on time per hour, day, week, or month

• Wire feed speed

• Welding parameters (A; V)

• Filler wire usage (kg)

• Energy consumption (kWh)

• Estimated gas consumption

• Welding machine details

Free trial for ArcVision

Activate your free 3-month trial license of WeldEye ArcVision with no obligation. The trial license also includes WeldEye’s Welding Procedures module, allowing you to test the digital WPS (dWPS) feature.

Take a look at WeldEye ArcVision

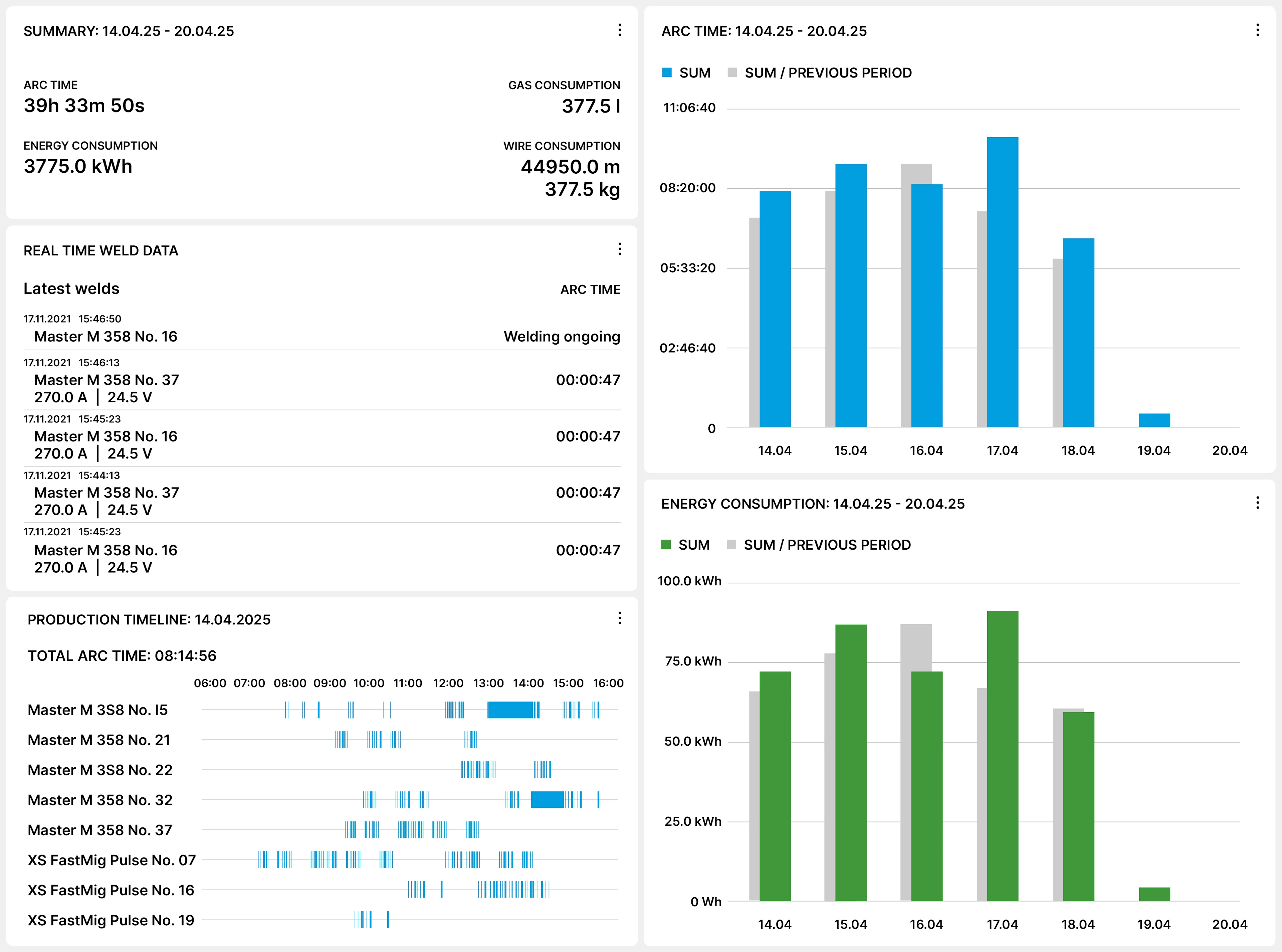

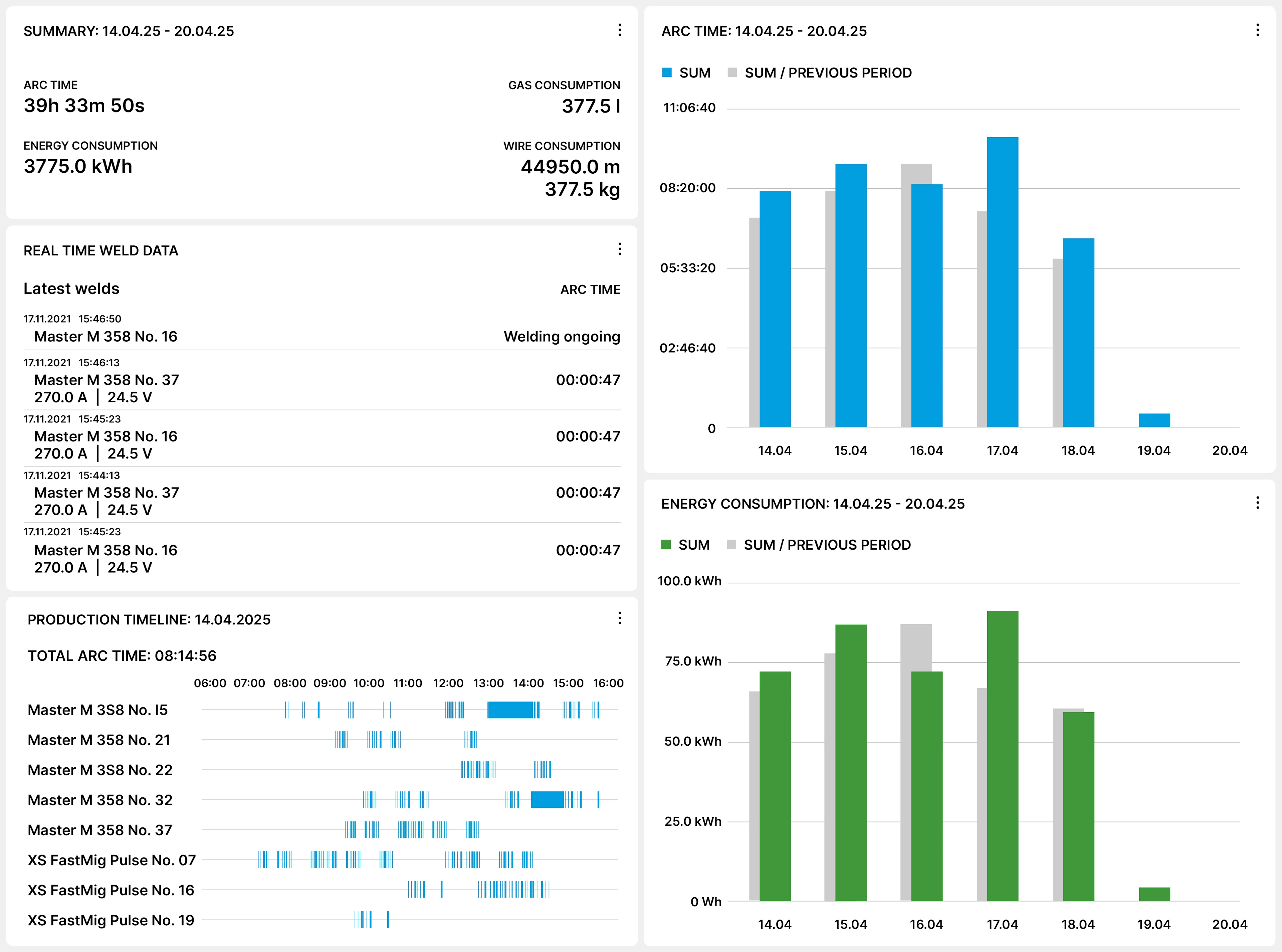

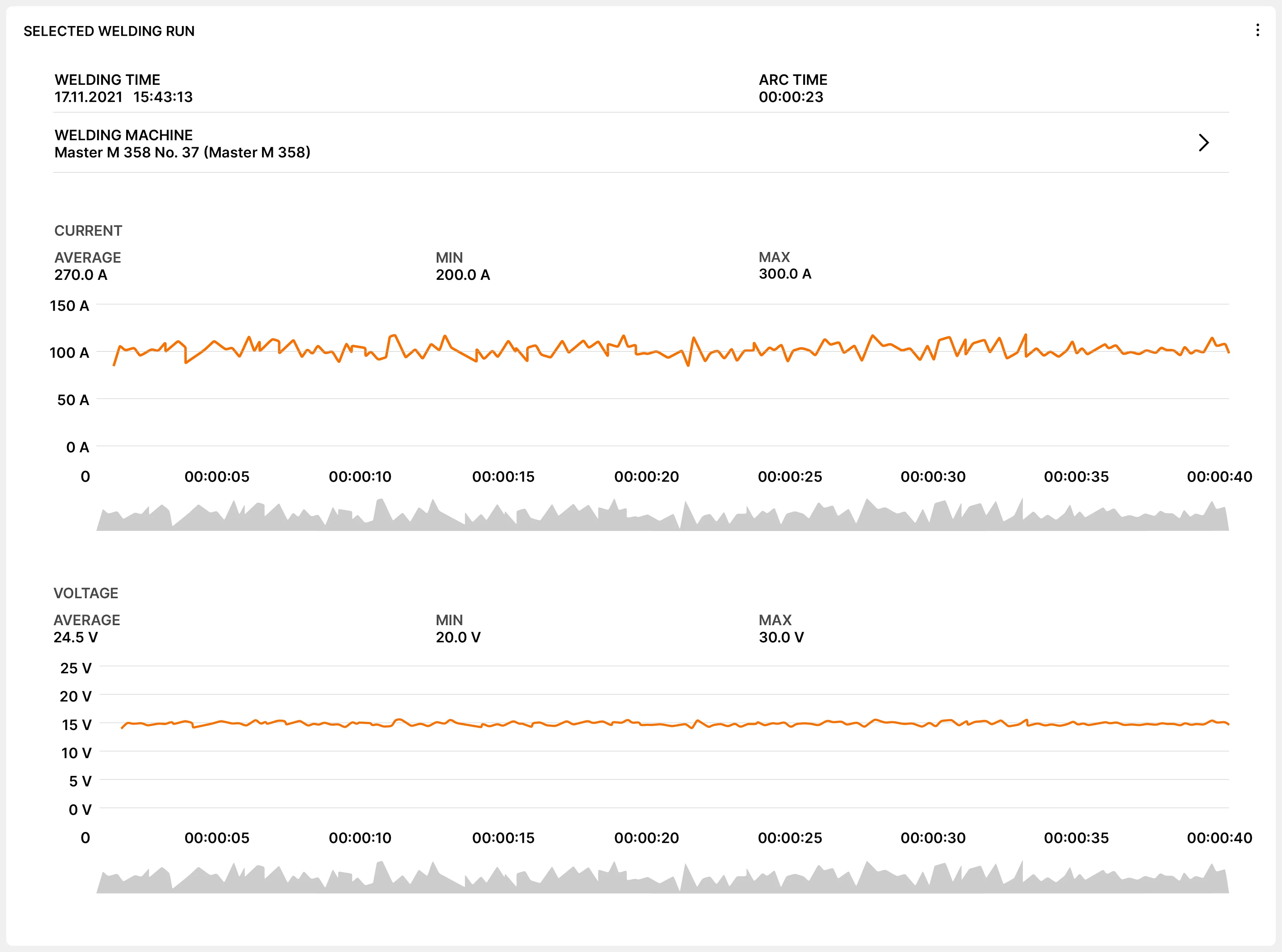

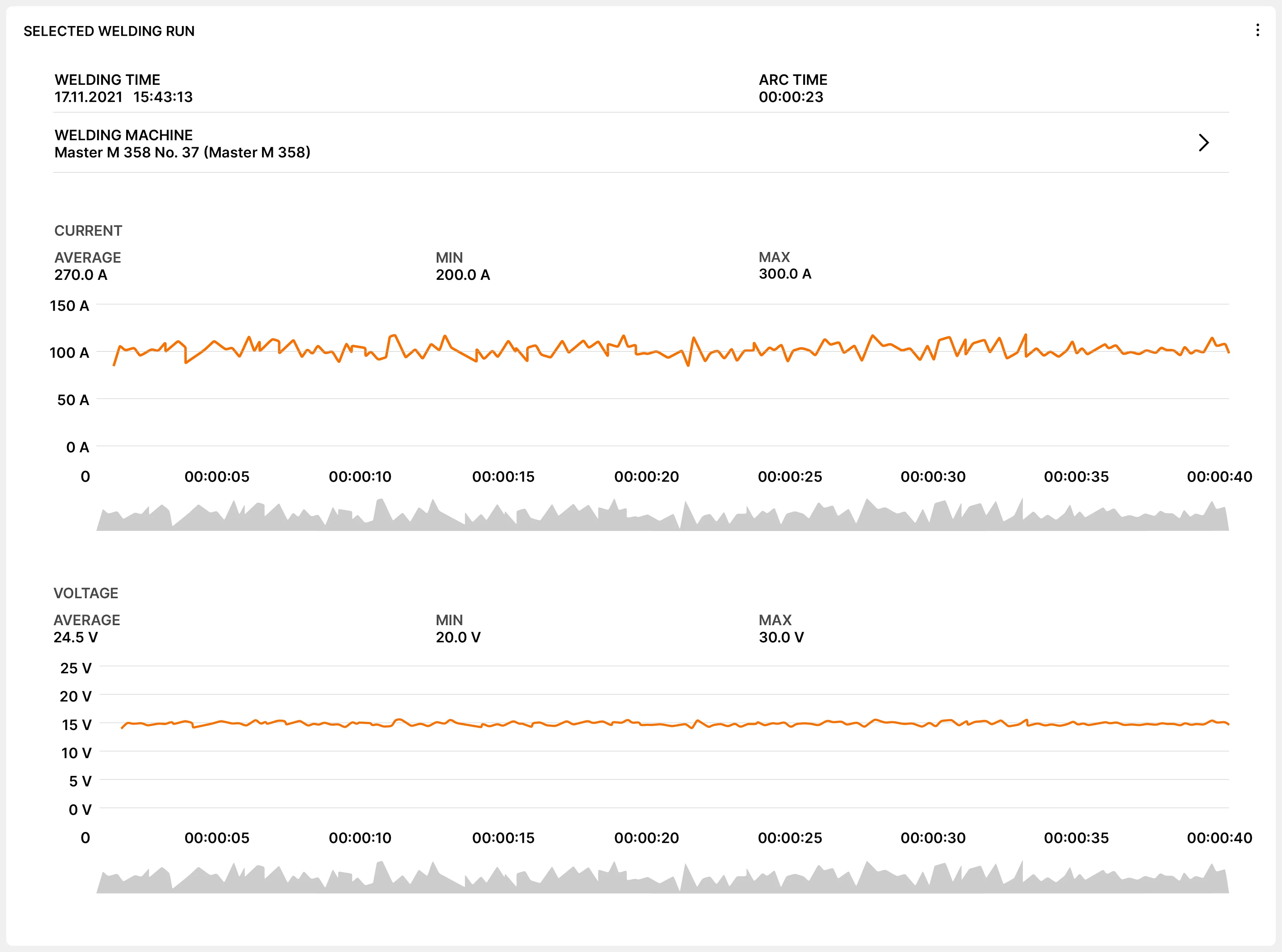

To support data analysis, WeldEye ArcVision produces user-friendly visualizations and comparison views to identify improvement potential in processes or working methods.

The overall view of WeldEye ArcVision sums up the welding production. It visualizes production's usage and consumption data into clear graphs.

The overall view of WeldEye ArcVision sums up the welding production. It visualizes production's usage and consumption data into clear graphs.

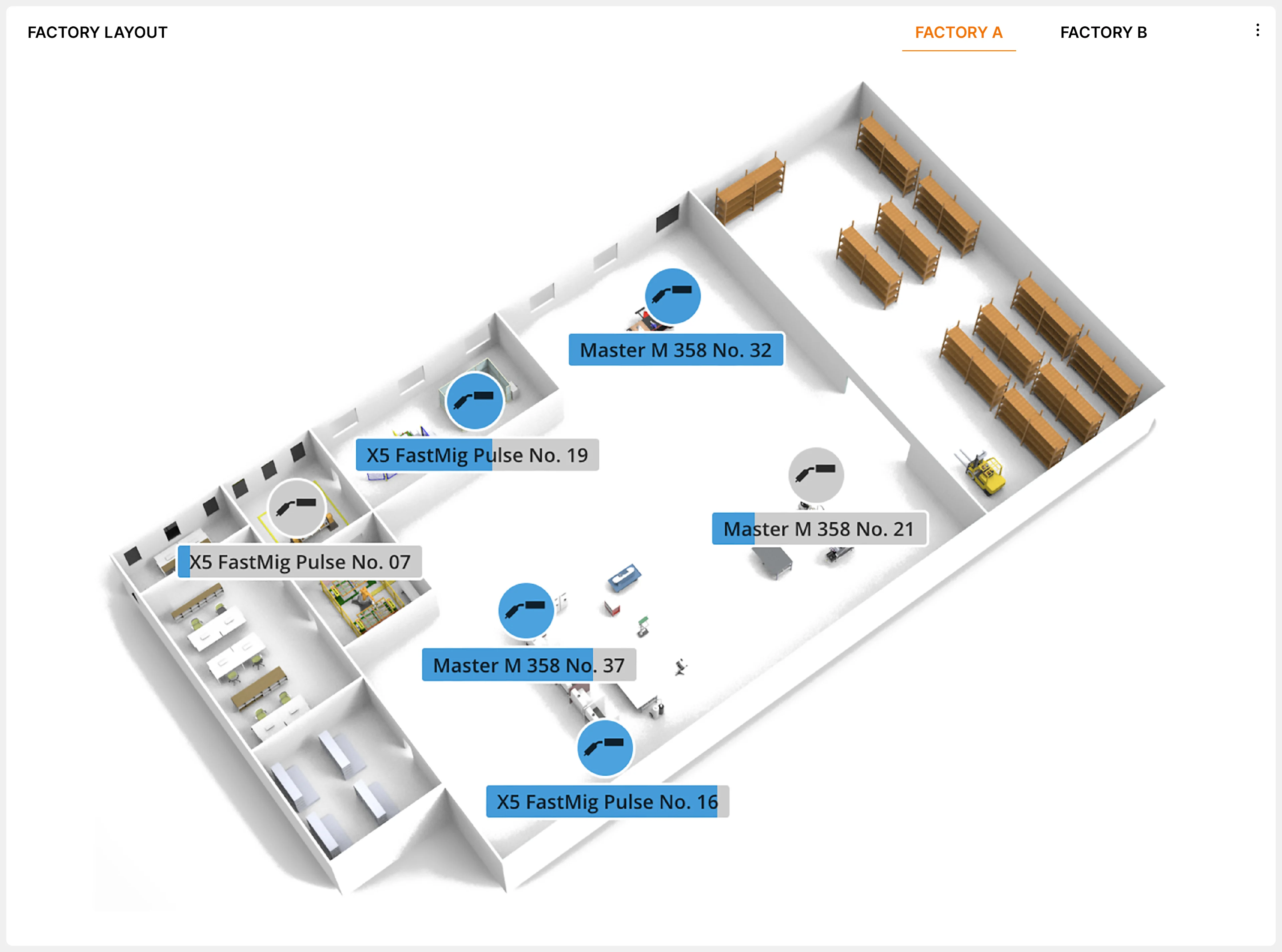

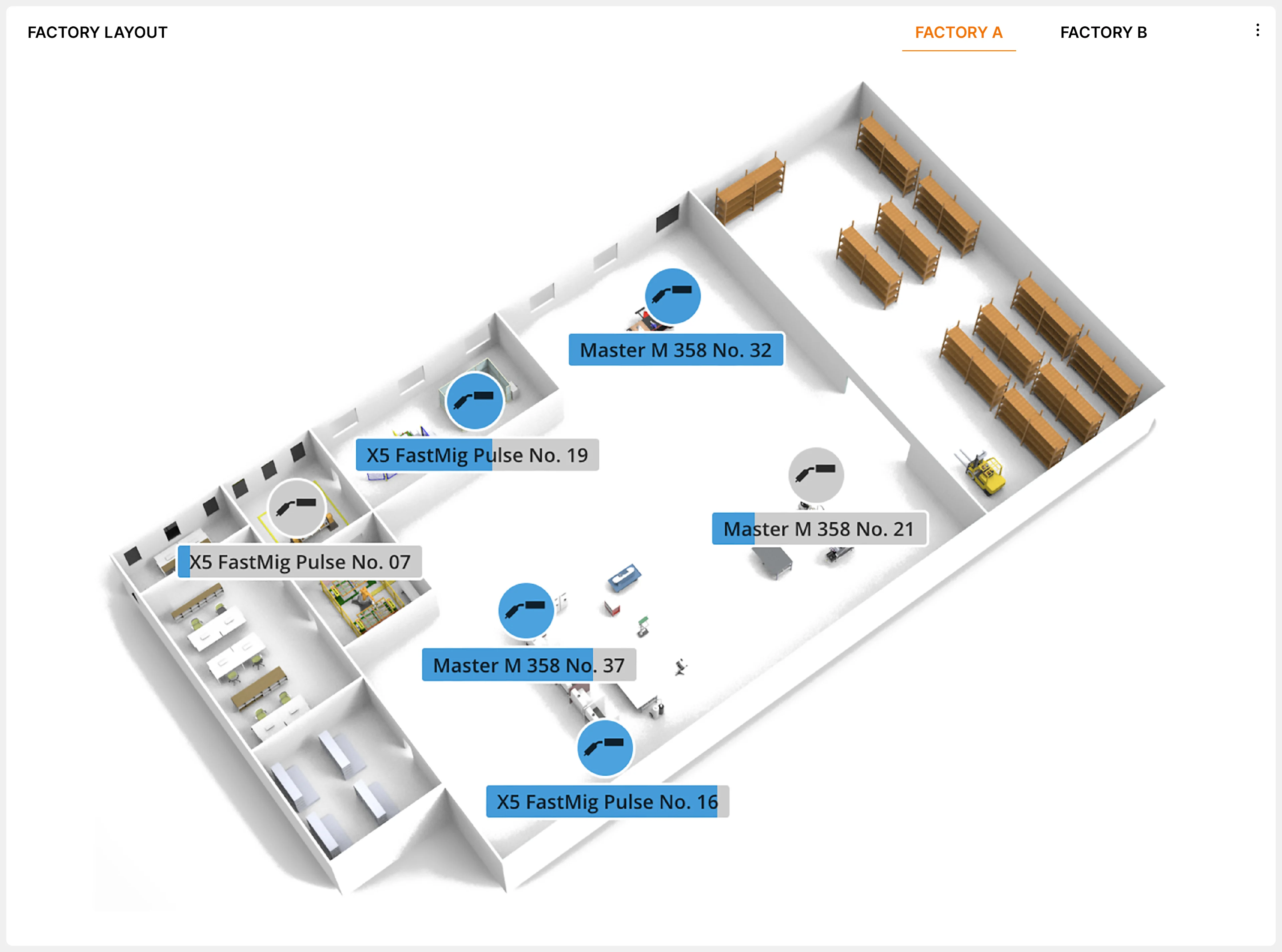

See each welding machine in the production plant's floorplan.

See each welding machine in the production plant's floorplan.

Used welding parameters are visible for each weld on a detailed level.

Used welding parameters are visible for each weld on a detailed level.

FAQ

Will WeldEye ArcVision get data from the rotameter about the welding gas usage?

Does WeldEye ArcVision itself comply with Industry 4.0 requirements, or is Welding Procedures module required to comply?

Does WeldEye ArcVision work with existing Kemppi machines like X8 MIG Welder?

Compatible welding machines

The WeldEye ArcVision is compatible with Kemppi welding machines with the newest user interface.

Master M 358 model

Compact MIG/MAG welder with manual, synergic (Auto), pulse (Auto Pulse), and double pulse welding options. Provides 350 A with a 40% duty cycle.

X5 FastMig with APC wire weeder

Versatile industrial multi-process welder with manual, synergic, pulse and auto-pulse functions.

Continuous production monitoring can increase arc-on time by up to 40%

In practice, this means shorter production lead times, which is especially great in the times of large projects and tight schedules.