Monitor arc-on time in welding production

WeldEye's Production Analysis is a light and cost-efficient software module that constantly tracks and measures the arc-on time of welding stations. It also provides information on the time spent on non-welding activities, such as grinding or gouging. The welding data is collected with a digital connectivity module that can be connected to your entire, multi-brand welding fleet. Even a simple solution for monitoring welding productivity can bring significant benefits for most companies and improve workflow planning in welding production.

Clear visuals

Cloud-based solution

Take a look at WeldEye Production Analysis

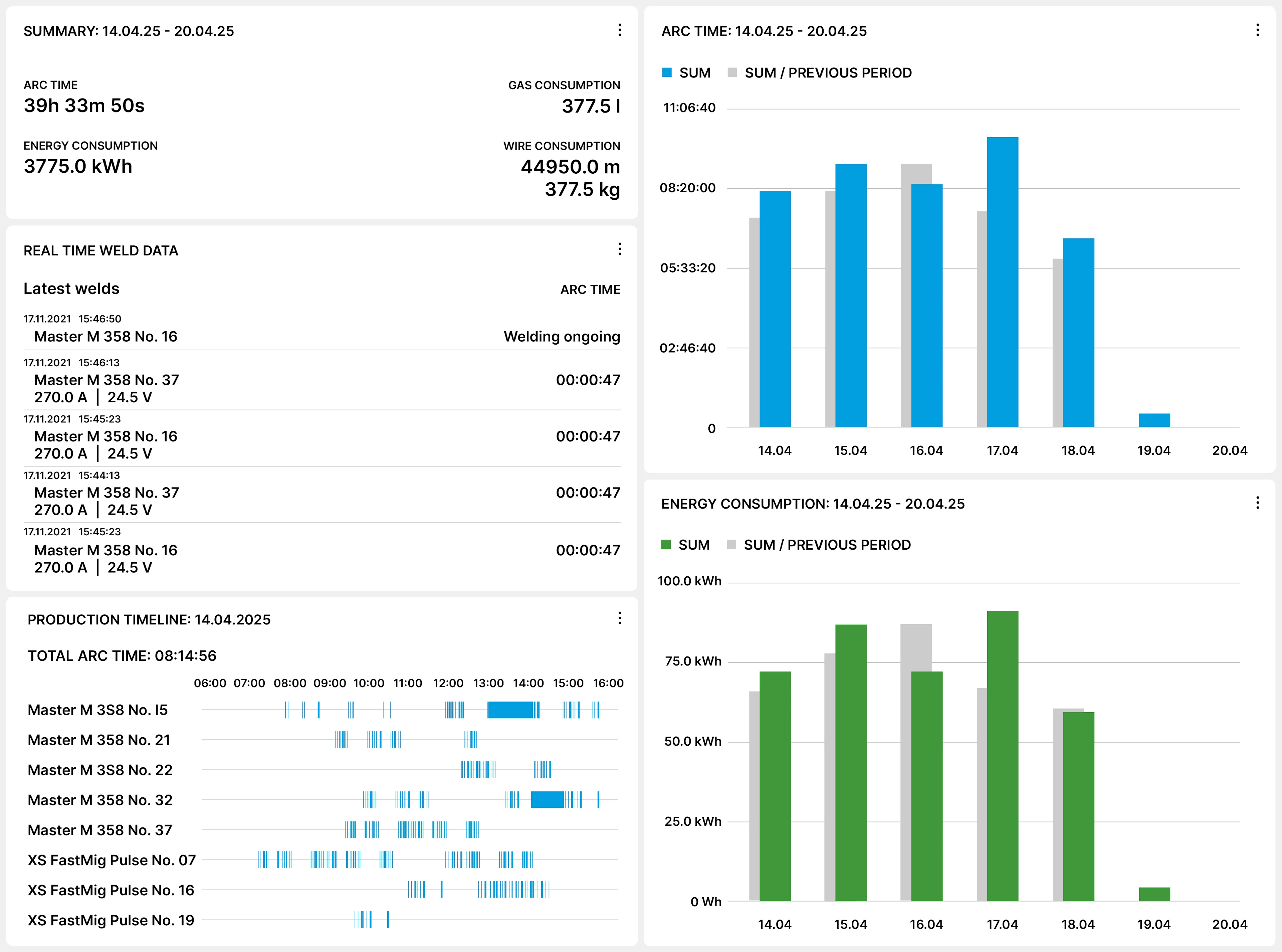

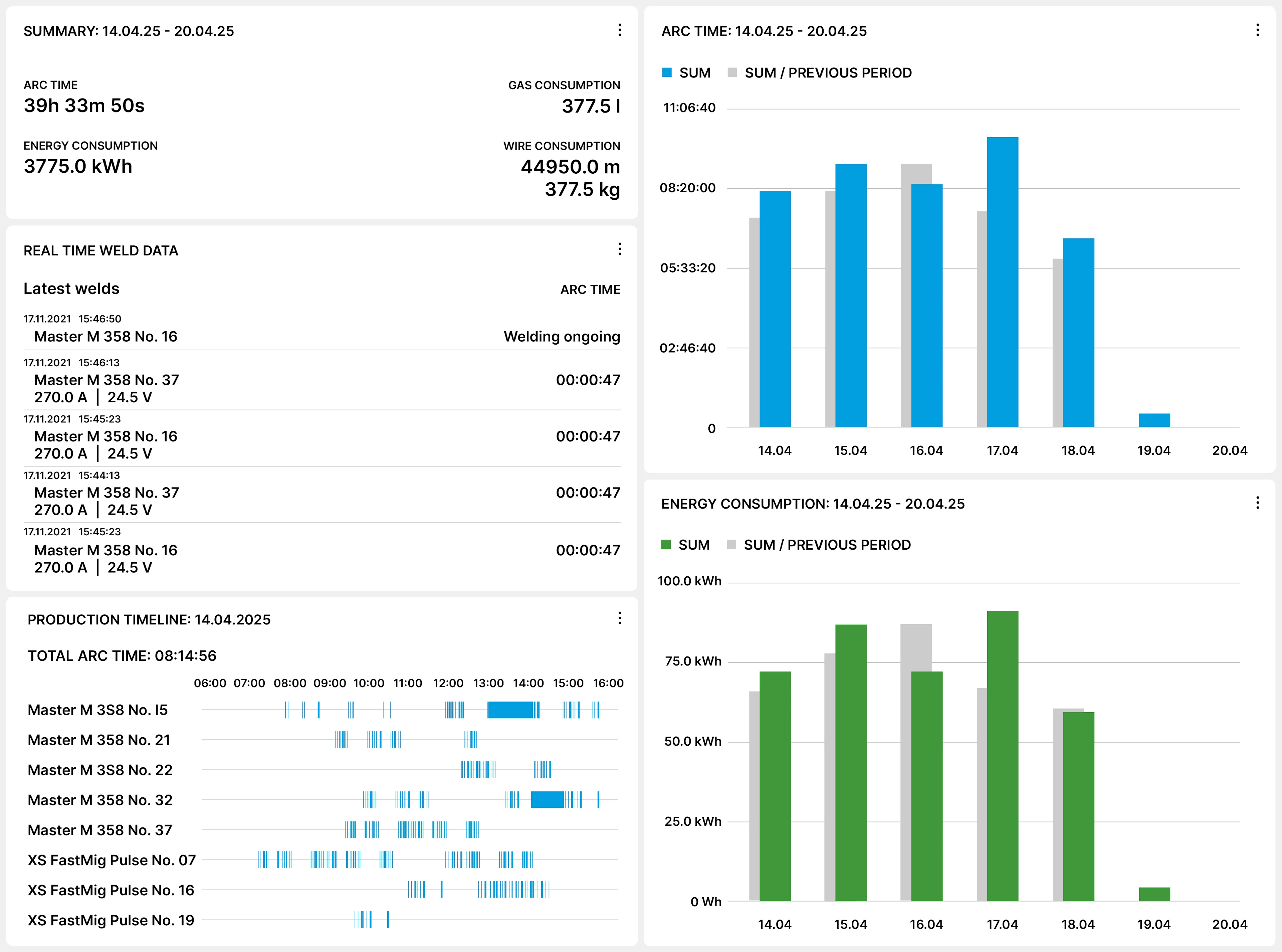

To support data analysis, WeldEye produces user-friendly visualizations and comparison views to identify improvement potential in processes or working methods.

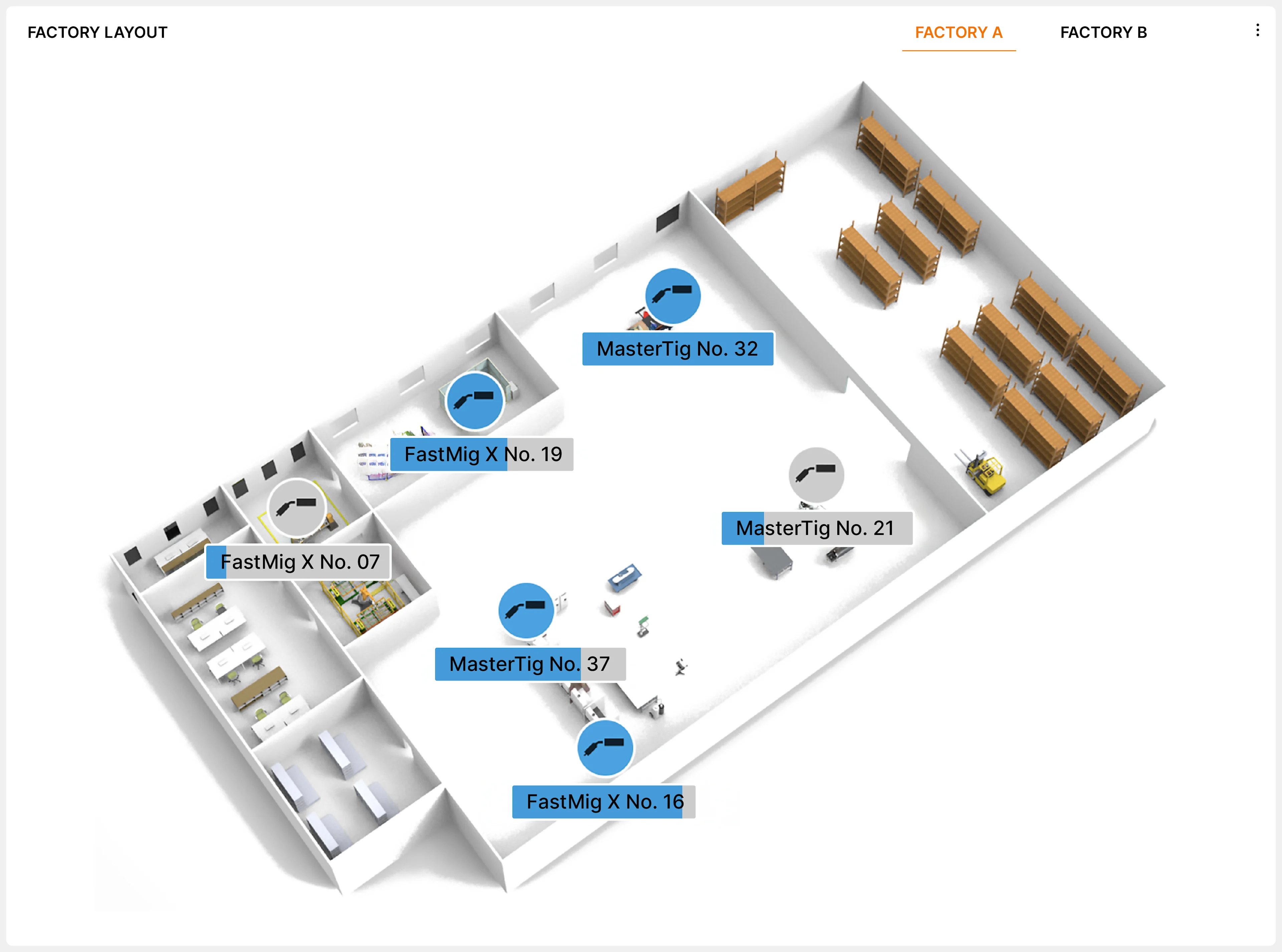

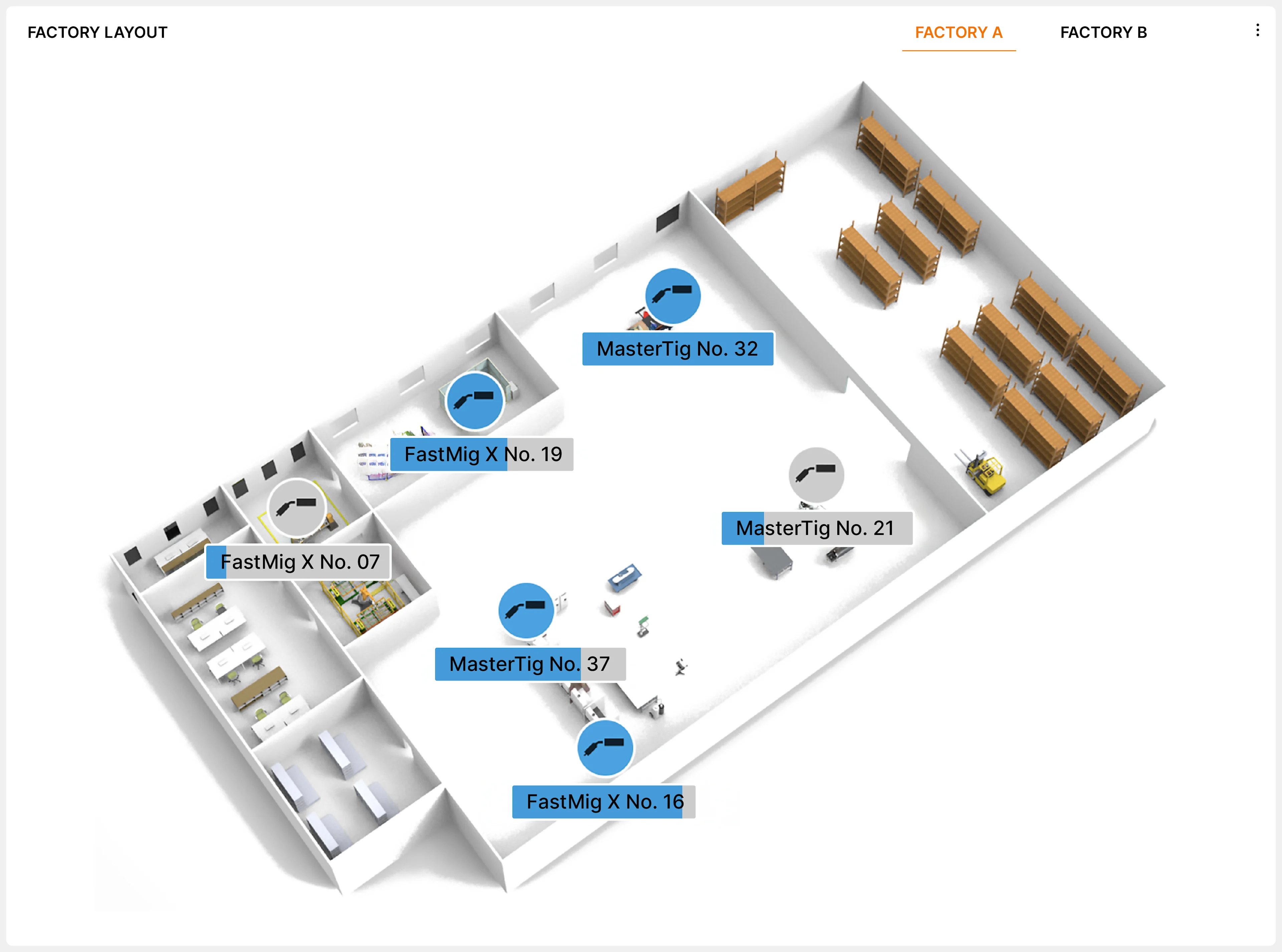

See active welding stations in your factory layout. Active stations are blue and inactive grey.

See active welding stations in your factory layout. Active stations are blue and inactive grey.

You can view total arc-on time within a selected time frame, and group it based on welding stations or personnel.

You can view total arc-on time within a selected time frame, and group it based on welding stations or personnel.

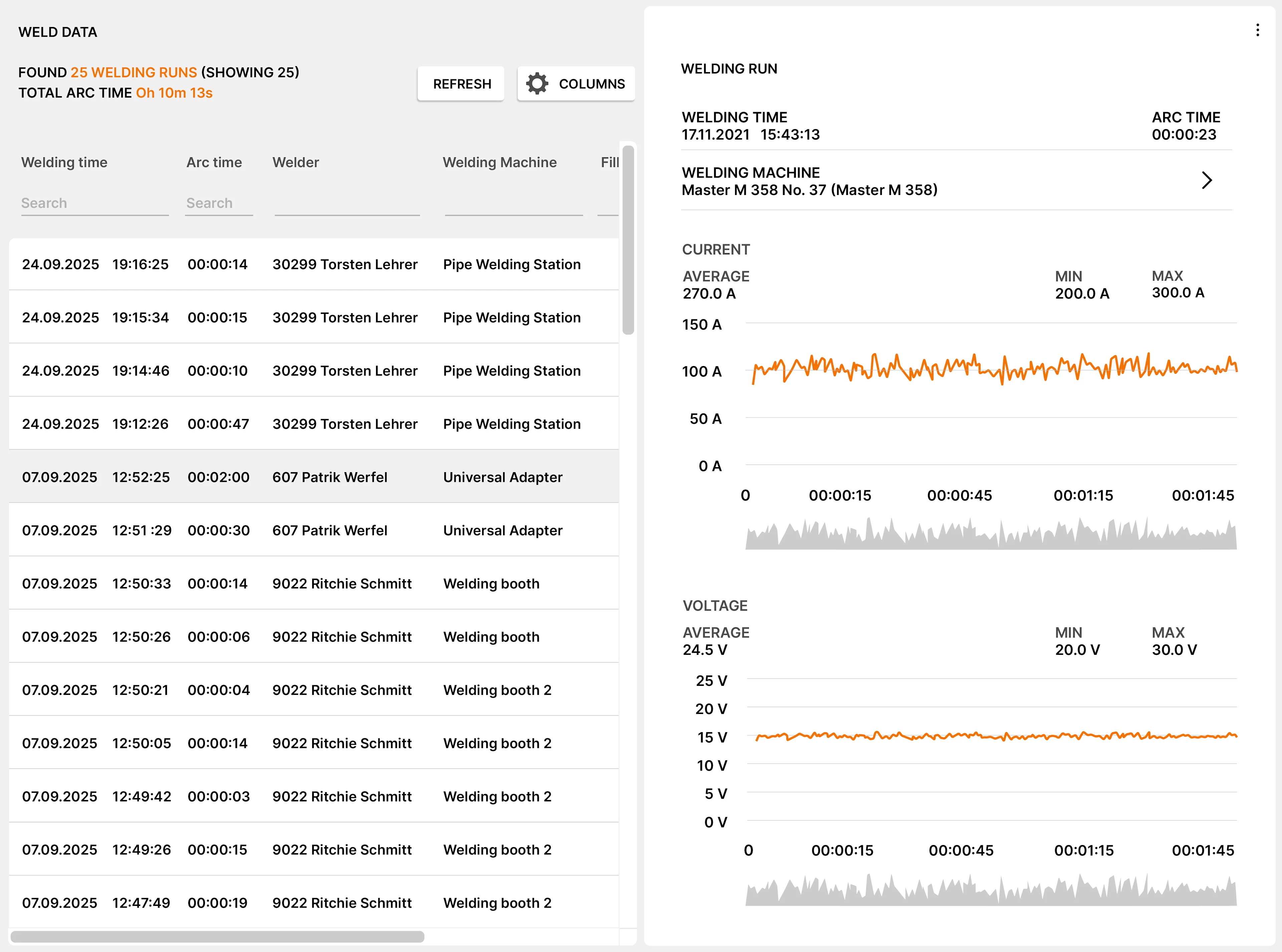

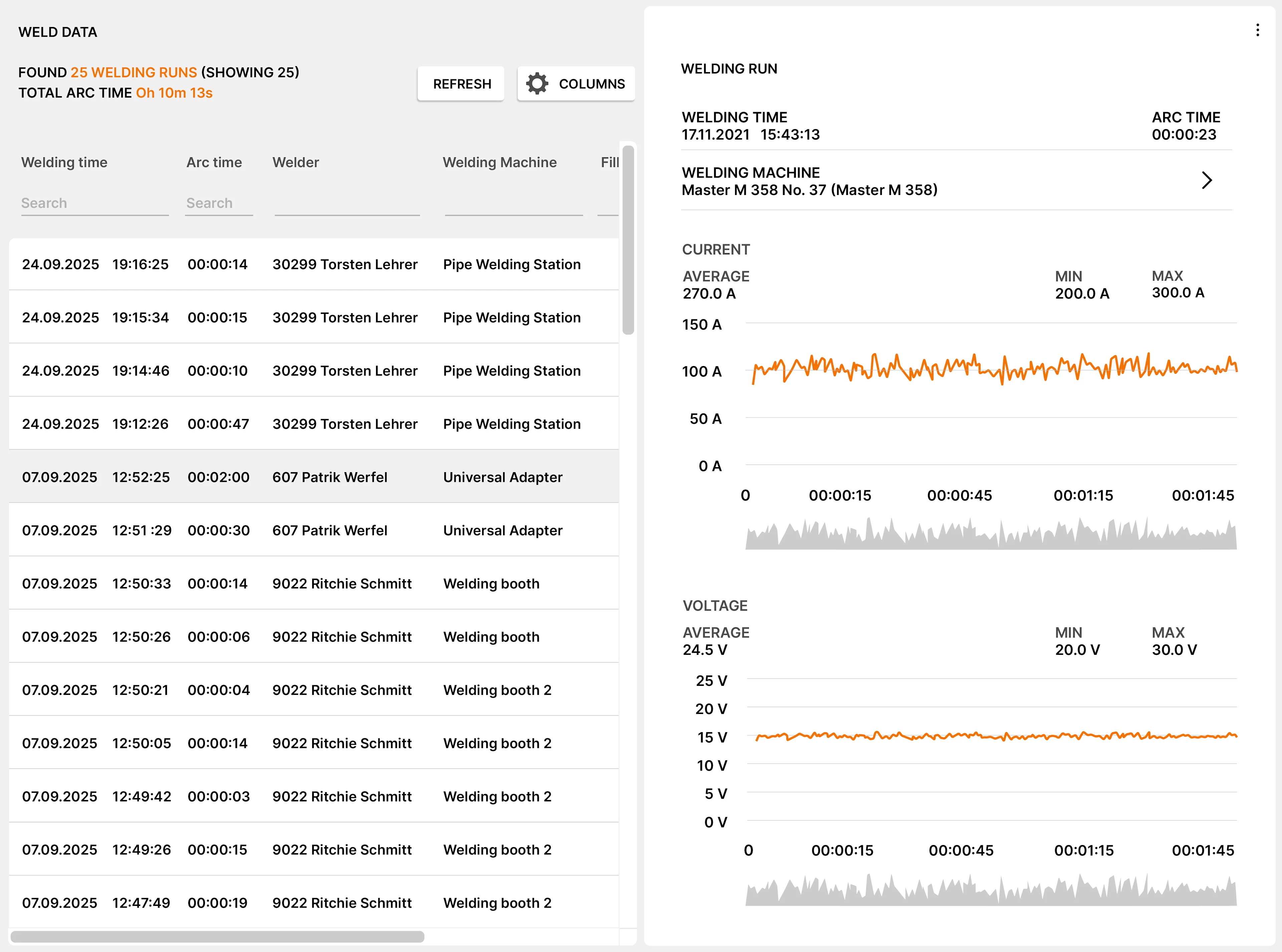

Review the welding runs against digitally collected welding parameters.

Review the welding runs against digitally collected welding parameters.

Optional adapters

The WeldEye adapters are accessory devices that enable universal connectivity with WeldEye's Digital Connectivity Module. The adapters measure current and voltage when connected to any brand's welding equipment.

6185930

6185930Euro Adapter – CV

6185930

For MIG/MAG welding equipment with Euro adapter.

6185911

6185911Universal Adapter – CV

6185911

For MIG/MAG, TIG or MMA welding equipment.

6185912

6185912Universal Adapter – TIG

6185912

For MIG/MAG, TIG or MMA welding equipment, includes a separate voltage-sensing connector.

6185920

6185920SAW Adapter

6185920

For SAW welding equipment.

Continuous production monitoring can increase arc-on time by up to 40%

In practice, this means shorter production lead times, which is especially great in the times of large projects and tight schedules.