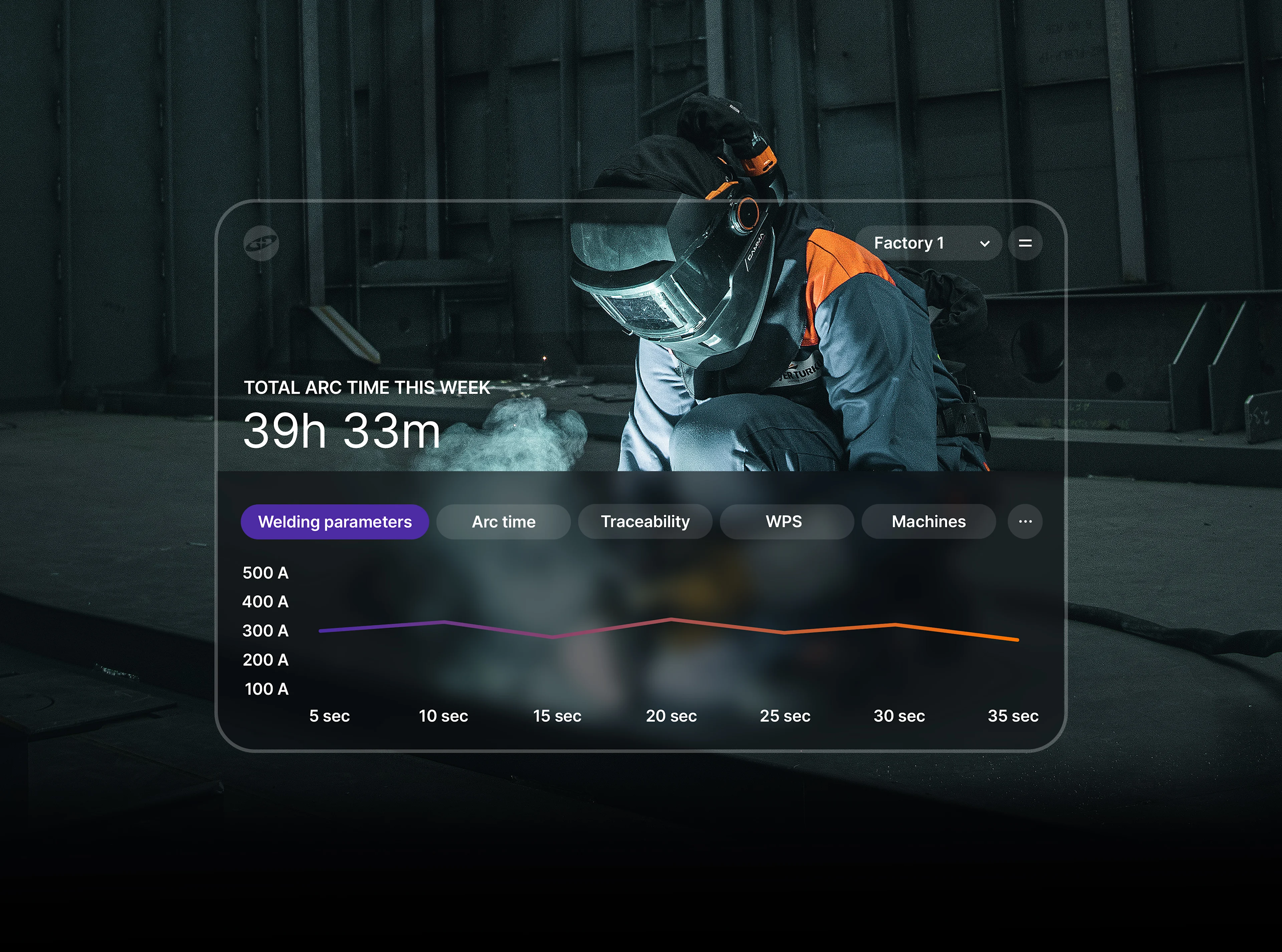

Quality Management

Collect welding parameters, measure heat input, and verify your compliance with welding standards.

Accurate welding quality control in real time

WeldEye's Quality Management is a universal, cloud-based software solution for verifying welding quality compliance with welding procedure specifications. By collecting welding parameter data from the workstations, the software produces valuable information and documentation about welding quality and provides 100% traceability for your welding production down to individual welds.

You will also be immediately notified of any welding deviations, which enables real-time quality control and ultimately reduces overhead costs. Various project management functions improve the monitoring of welding project progress and support the centralization of project documentation under one software solution.

In addition to Quality Control module, WeldEye's Welding Quality Management solution includes Fleet Management, Production Analysis, and Welding Procedures and Personnel Qualifications modules.

Future-proof welds

Universal solution

Welding Quality Management solution

100% traceability

Quality Control is a part of the WeldEye for Welding Quality Management software, which verifies welding quality and provides modern tools for easy and efficient management of welding procedures and welders' qualification certificates.

100% traceability

Quality Control is a part of the WeldEye for Welding Quality Management software, which verifies welding quality and provides modern tools for easy and efficient management of welding procedures and welders' qualification certificates.

Reduce risks with accurate data

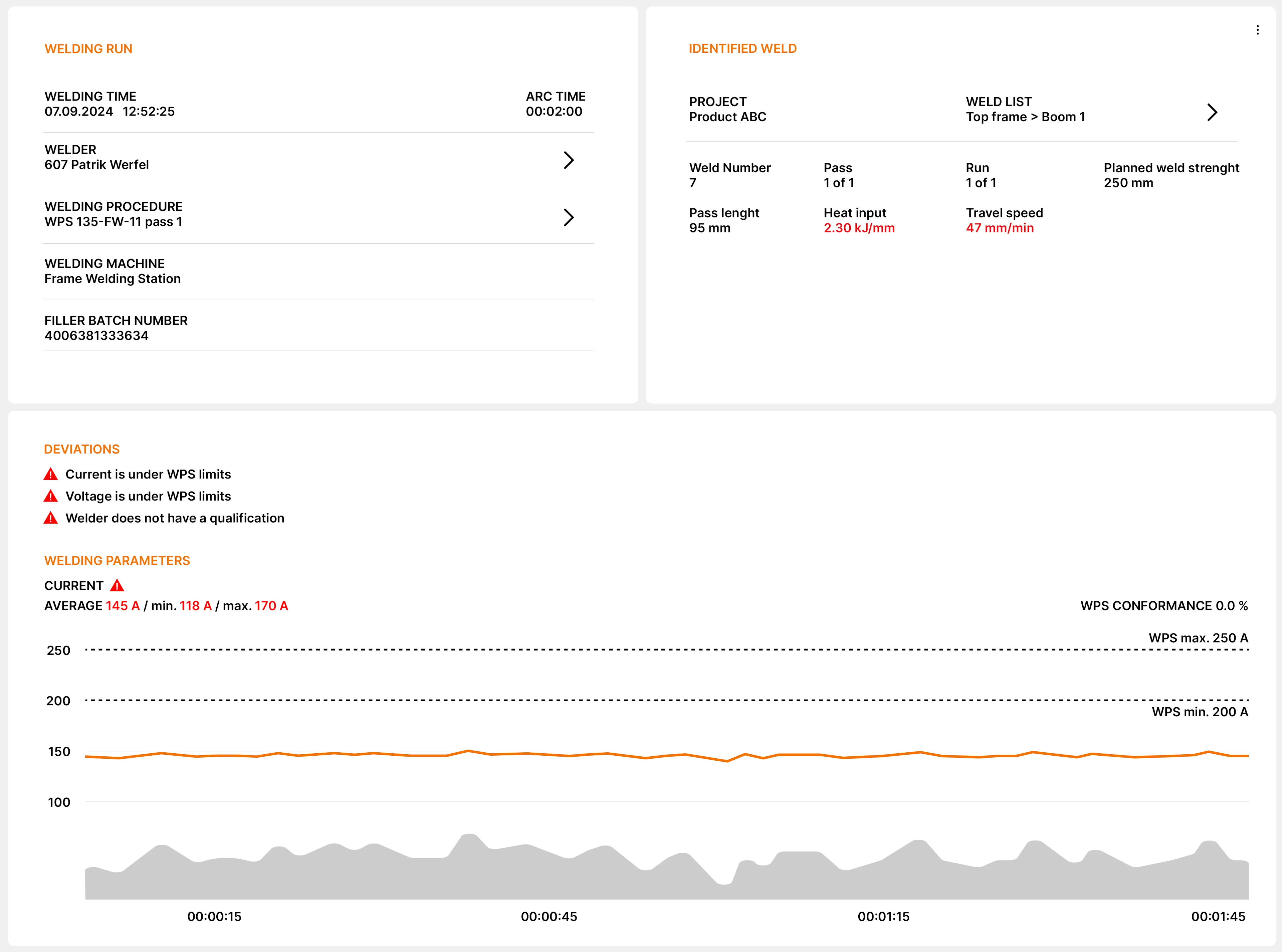

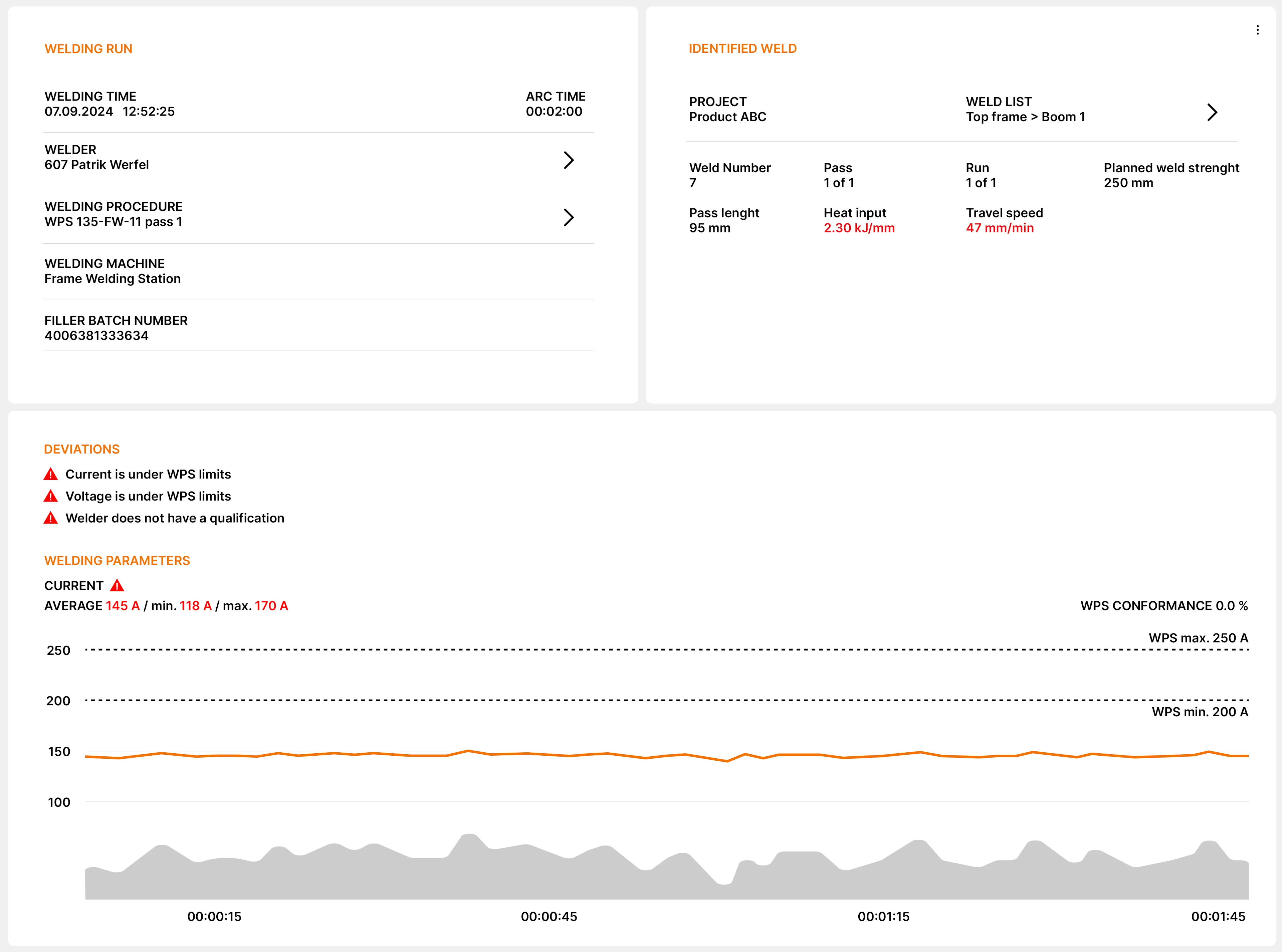

When connected to welding equipment, WeldEye collects data on the used welding parameters (voltage, current, and wire feed speed) and utilizes the information to calculate heat input and average welding speed.

When all the necessary data is digitally collected by the software, you reduce the risk of miscalculations and no longer need an extra person to observe the welding parameters or report the heat input manually.

Take a look at WeldEye Quality Management

With WeldEye, you will know for sure that your welds comply with global welding standards. Any deviations, including those that could not be caught in NDT inspections, are reported immediately.

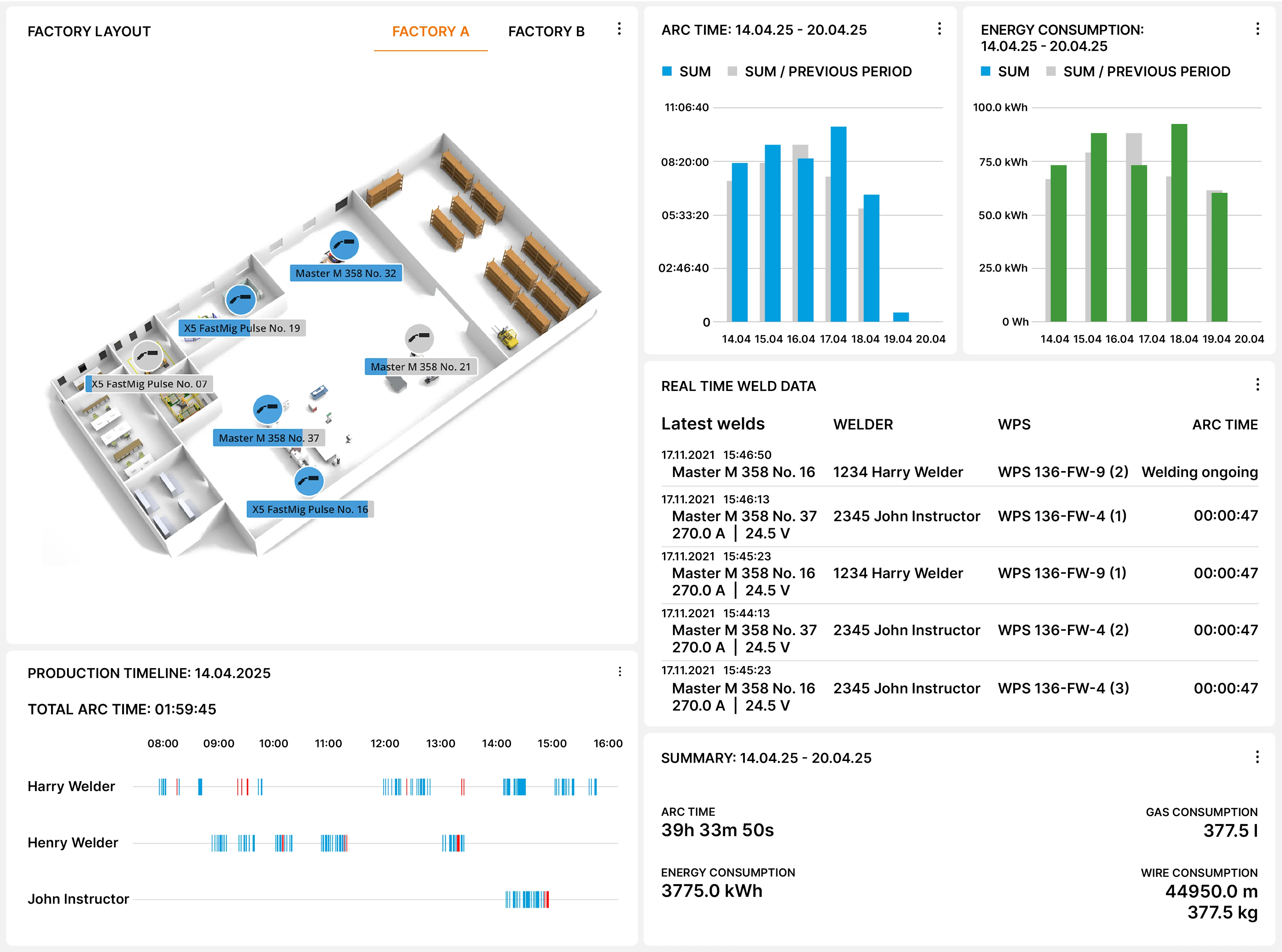

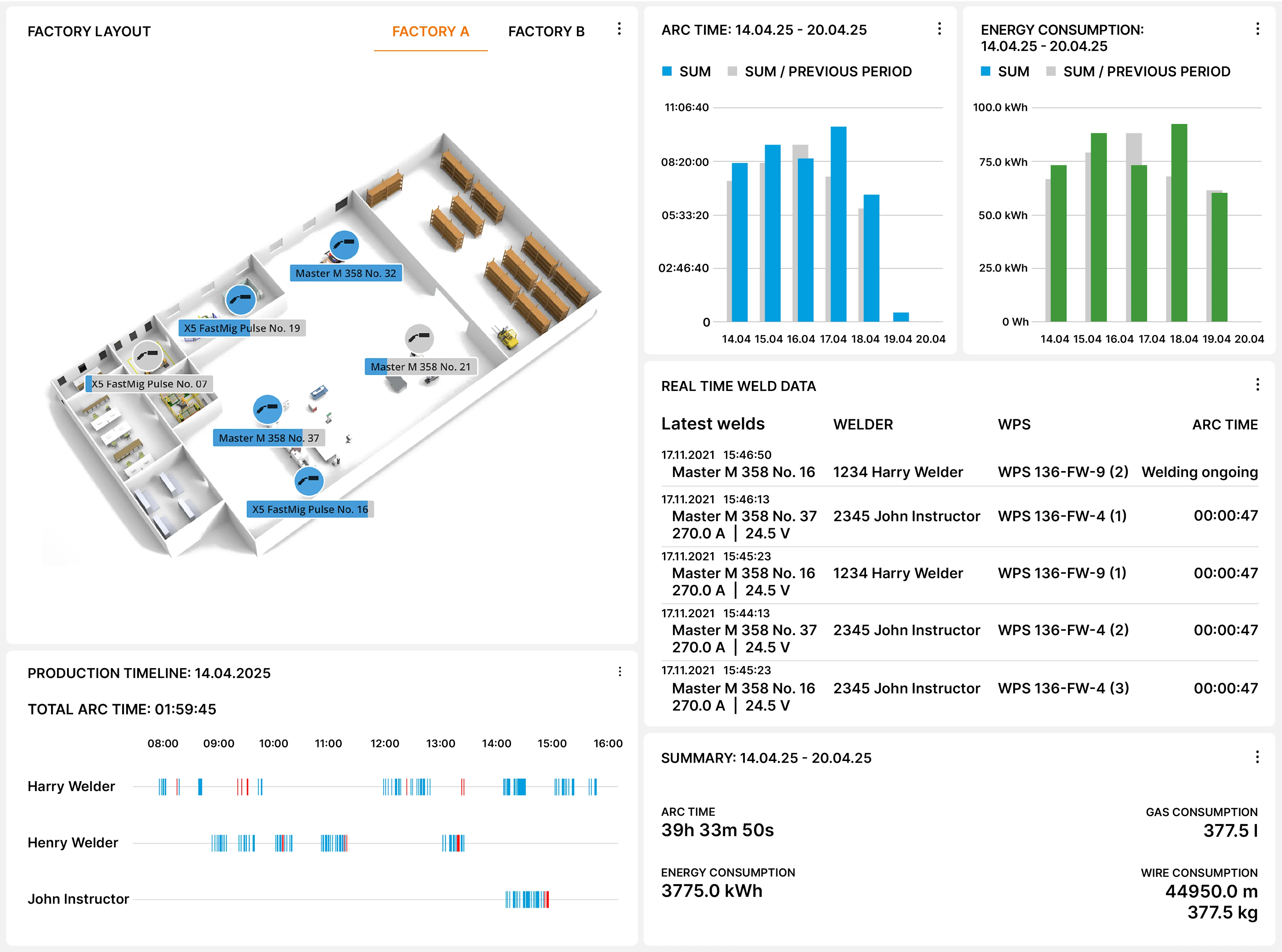

See active welding stations in your factory layout, view total arc-on time and energy consumption within a selected time frame, and see the latest welds by each welder accoring to the WPS.

See active welding stations in your factory layout, view total arc-on time and energy consumption within a selected time frame, and see the latest welds by each welder accoring to the WPS.

Review the welding runs against digitally collected, detailed welding-parameter data and heat-input calculations.

Review the welding runs against digitally collected, detailed welding-parameter data and heat-input calculations.

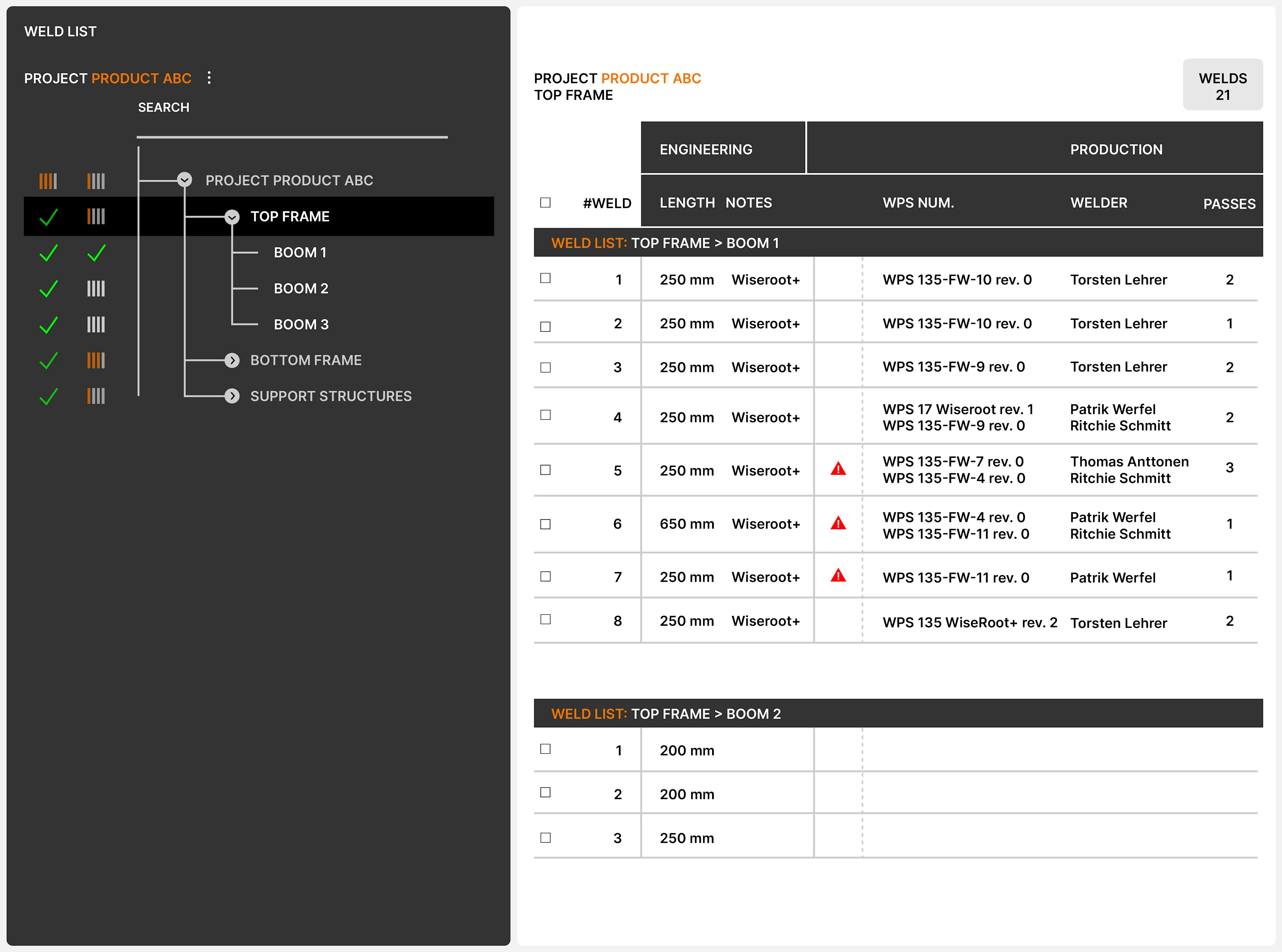

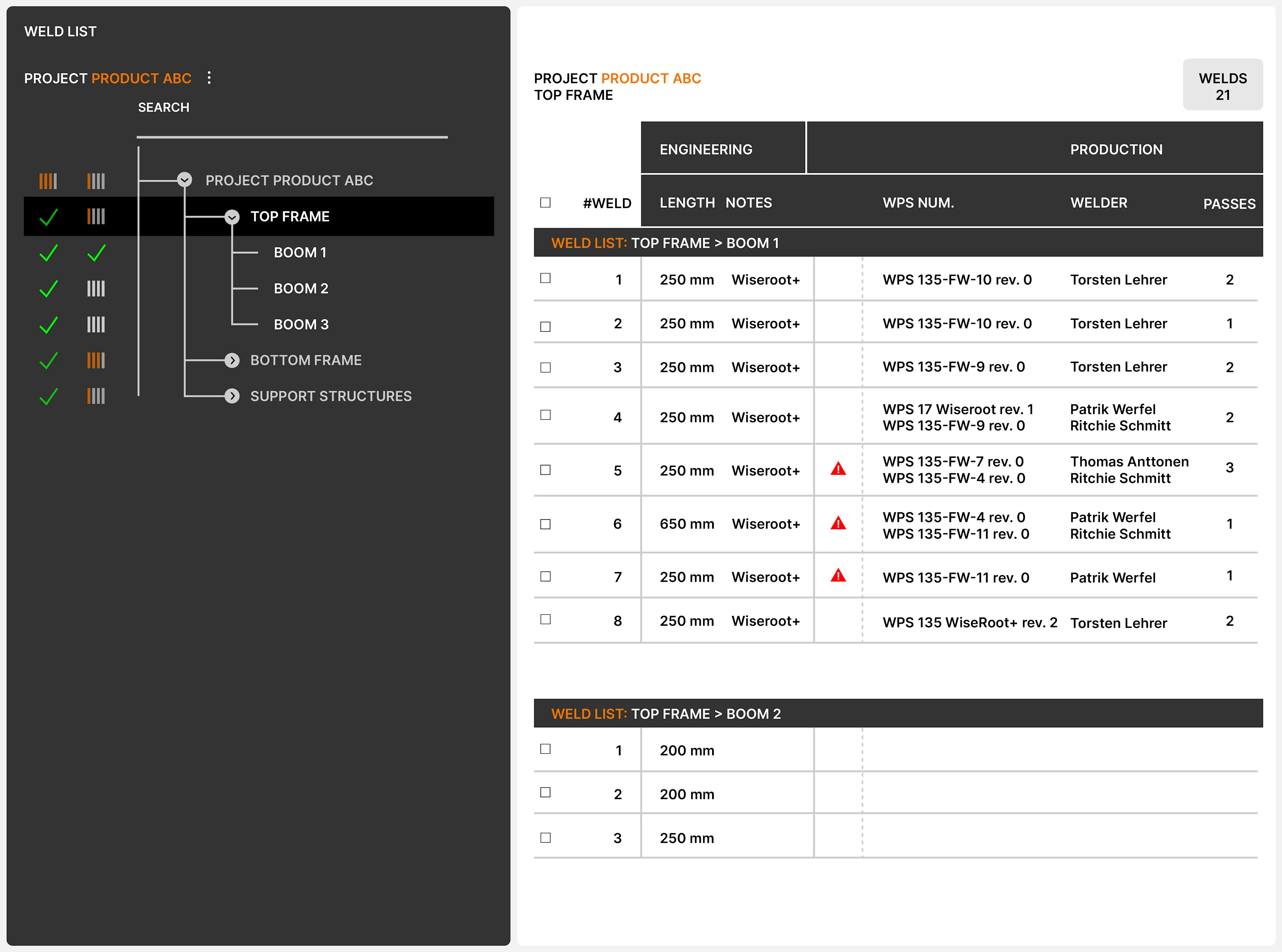

Manage your weld lists and create identifiers, such as bar codes or QR codes, for weld traceability.

Manage your weld lists and create identifiers, such as bar codes or QR codes, for weld traceability.

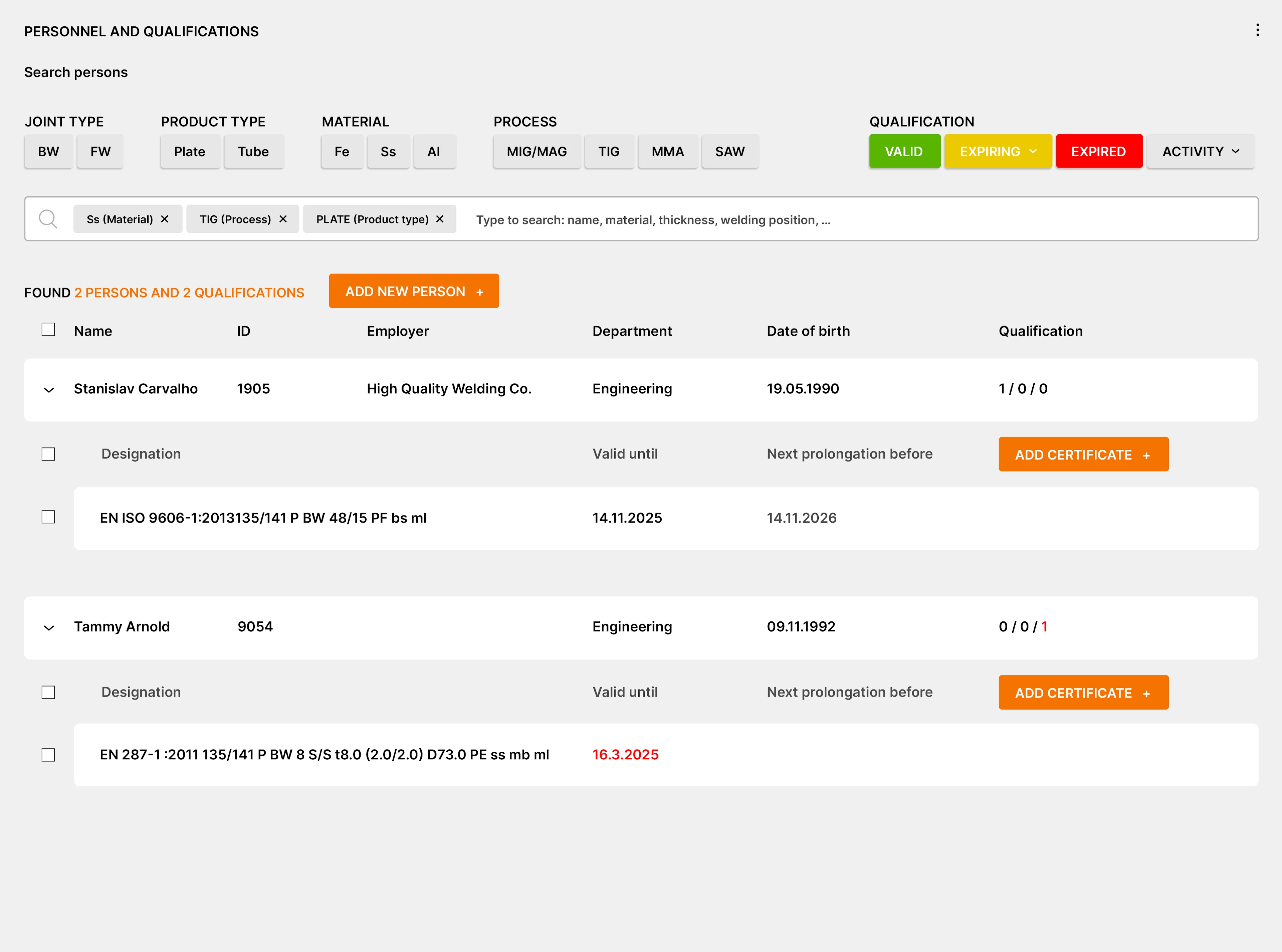

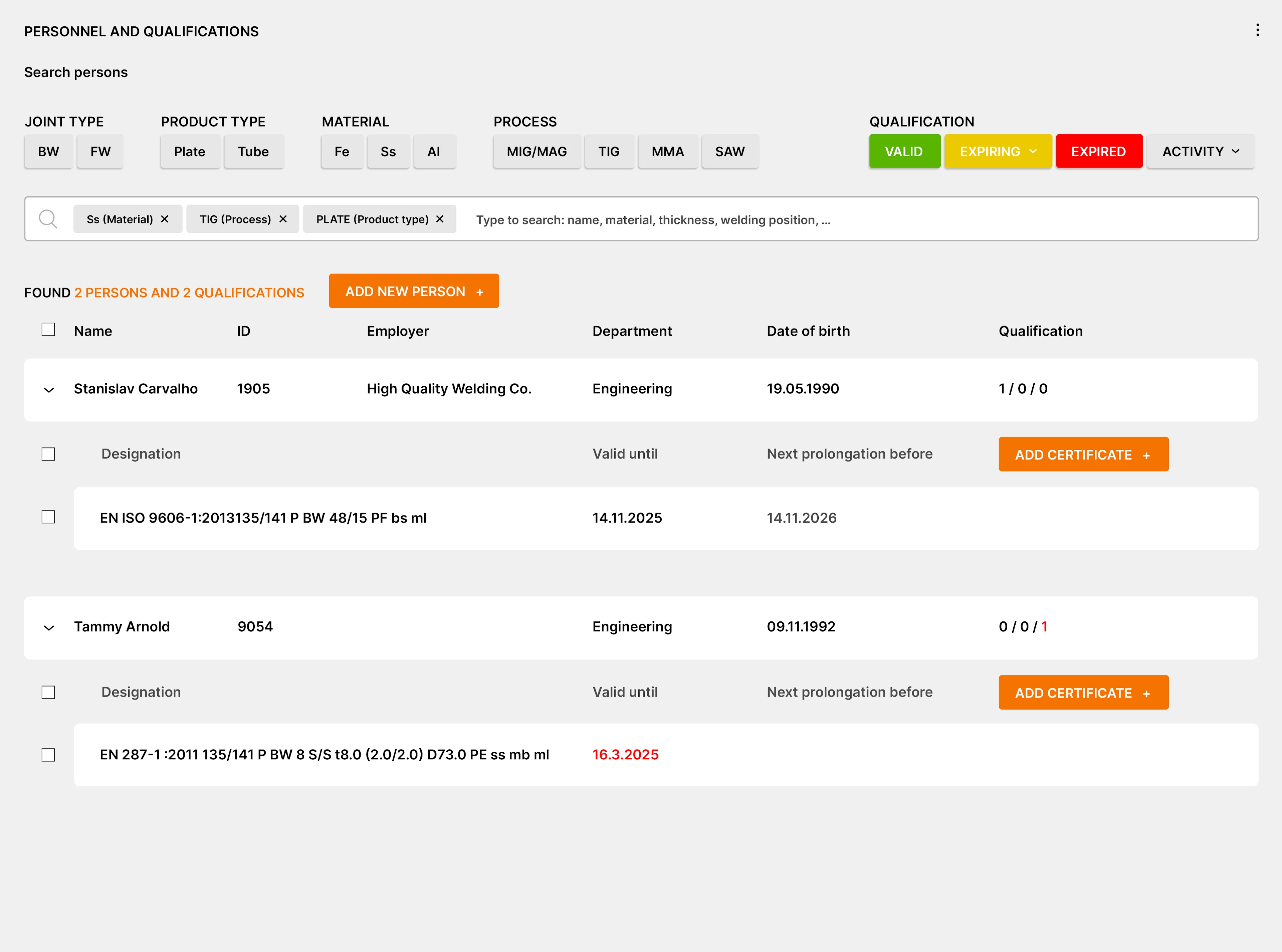

Browse your welders’ qualification certificates in one view, check their expiry, and handle prolongations with just a few clicks.

Browse your welders’ qualification certificates in one view, check their expiry, and handle prolongations with just a few clicks.

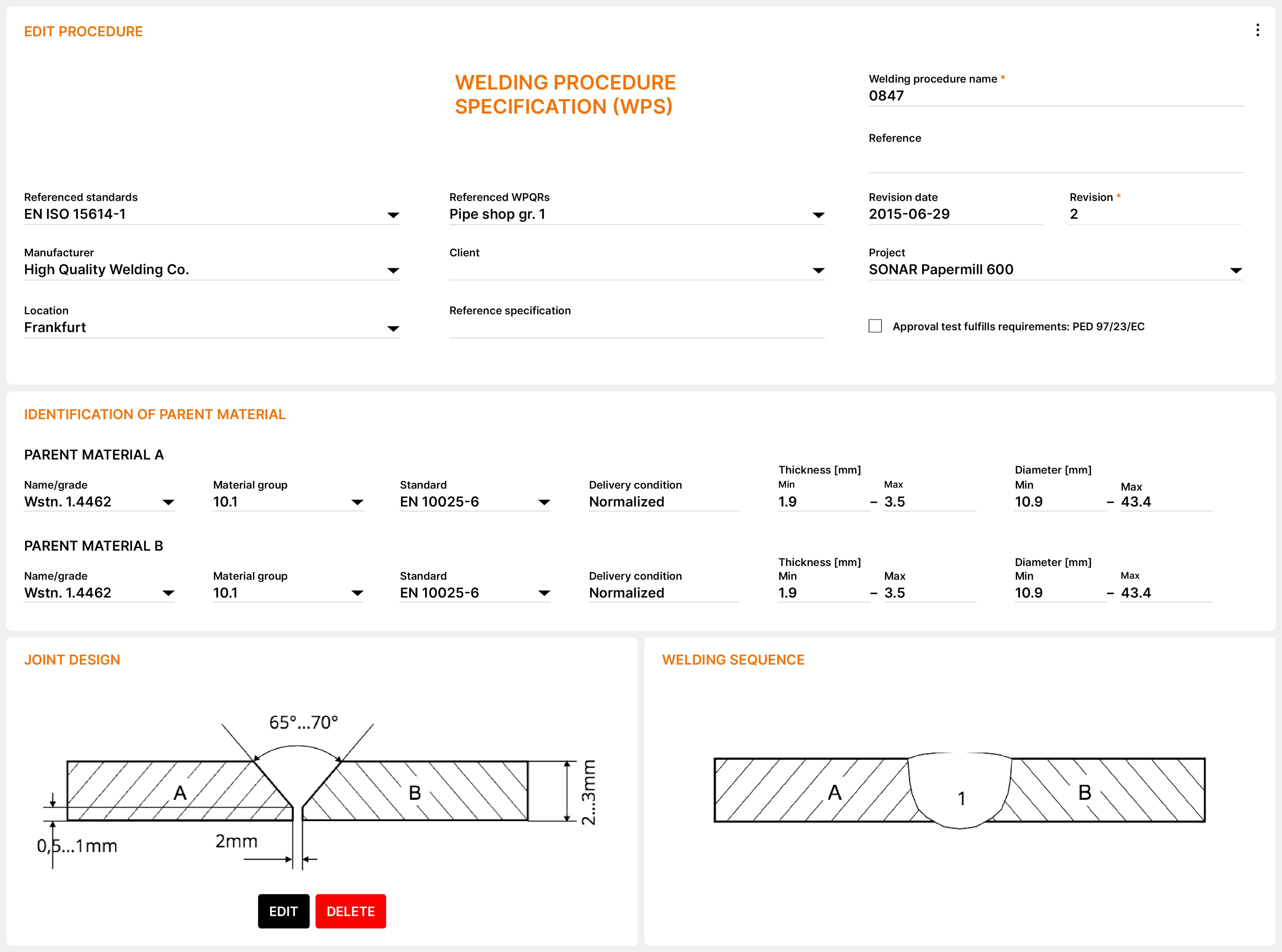

The digitally stored documents can be easily revised, uploaded and shared in pdf format, and printed out when needed.

The digitally stored documents can be easily revised, uploaded and shared in pdf format, and printed out when needed.

Wireless data transfer

By using the WeldEye mobile application, welders are able to browse their company's WPS library, receive digital work orders, report work progress, and get feedback on their welds – including heat input values.

Together with WeldEye's Digital Connectivity Module (DCM), the WeldEye app serves as a convenient and cost-efficient tool that enables digital workflow management and welding quality control. Download the app free of charge to any mobile device with Android 8.0 or newer from Google Play. Its use requires synchronization with an active WeldEye for Welding Quality Management account.

Optional adapters

The WeldEye adapters are accessory devices that enable universal connectivity with WeldEye's Digital Connectivity Module. The adapters measure current and voltage when connected to any brand's welding equipment.

6185930

6185930Euro Adapter – CV

6185930

For MIG/MAG welding equipment with Euro adapter.

6185911

6185911Universal Adapter – CV

6185911

For MIG/MAG, TIG or MMA welding equipment.

6185912

6185912Universal Adapter – TIG

6185912

For MIG/MAG, TIG or MMA welding equipment, includes a separate voltage-sensing connector.

6185920

6185920SAW Adapter

6185920

For SAW welding equipment.

Transparent welding quality control can reduce weld repair rate by up to 40%

Early intervention on any welding deviations can bring significant cost savings, and overall quality can only be improved through increased knowledge. Would you like to know more?