Jayben Group adopted Kemppi’s WeldEye welding management software to gain full visibility into welding quality and compliance across operations. WeldEye enabled real-time monitoring, simplified documentation, and helped Jayben stay on track with growing demands in the defense and industrial sectors.

Australian OEM manufacturer boosts compliance with WeldEye

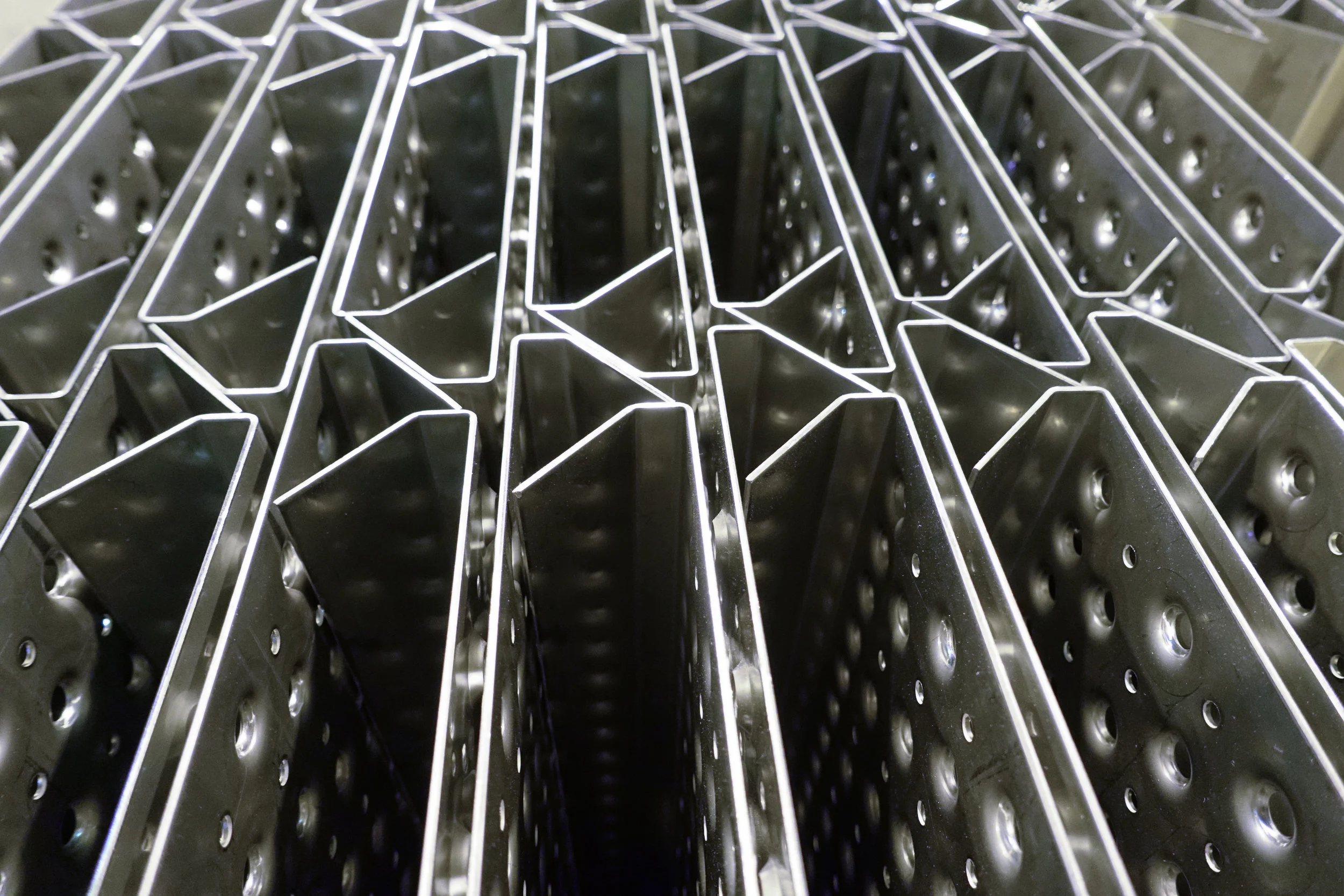

Jayben Group is an Australian OEM manufacturer with a legacy dating back to 1927. Headquartered in Tasmania with operations also in South Australia, Jayben designs and manufactures power train products and industrial equipment for mining, agriculture, manufacturing, and defense customers. Known for its high-quality standards, the company continuously seeks solutions that align with its growth and operational excellence, especially in welding performance and traceability.

Ensuring weld quality across diverse equipment during rapid growth

Despite having skilled welders and reliable machines, Jayben lacked a way to objectively track welding accuracy and consistency. With growing demand, particularly in the defense sector, the company needed a comprehensive solution that could deliver real-time monitoring, maintain quality across varied equipment, and support rigorous compliance standards without disrupting its existing welding fleet.

“Welding is fundamental when you’re manufacturing. The welds in our equipment are used in some of the harshest environments. It doesn’t matter the metal or the fit—weld quality is what really counts,” says Danny Patmore, Fabrication Manager at Jayben Group.

WeldEye confirmed we were on the right track. It added confidence in our quality checks, and its reporting functions save us countless hours. We’ve already recommended it to others.Danny PatmoreFabrication Manager, Jayben Group

Real-time welding traceability and compliance made easy

Jayben turned to Kemppi WeldEye, a universal welding management solution designed to support high-performance welding operations. The software’s compatibility with all welding machine brands allowed Jayben to keep and manage its existing fleet, while introducing traceability, automated quality monitoring, and centralized documentation.

“WeldEye was the only system we came across that offered what we wanted and was compatible with the brands we already had. We had six welders with their own preferred machines, so we didn’t want to go out and get six of the same brands. We didn’t want to have to go out and buy new equipment,” says Danny.

One of the most valued features was the ability to track welding parameters in real time. “WeldEye lets us monitor welding quality as the welds are laid down, and we can flag any issues,” says Danny Patmore. “This means we can detect deviations early and take corrective actions immediately.”

Jayben also appreciates the ability to produce qualitative data and reports at the touch of a button for customers’ quality assurance needs.

In addition to supporting real-time quality control, WeldEye streamlined the creation and management of welding procedure specifications (WPS) and personnel qualifications. As all data is stored in one place and can be accessed with just a few clicks, new staff can be assessed and upskilled faster.

Today, WeldEye supports Jayben’s entire welding operation, from manual stations to Kemppi’s robotic welder, ensuring consistency and compliance with standards like AS/NZS ISO 3834. Jayben continues to see strong growth, particularly in defense work, and the incorporation of aluminum welding solutions has expanded its product line. The company credits WeldEye with improving operational efficiency and reinforcing its position as a trusted supplier in demanding sectors.