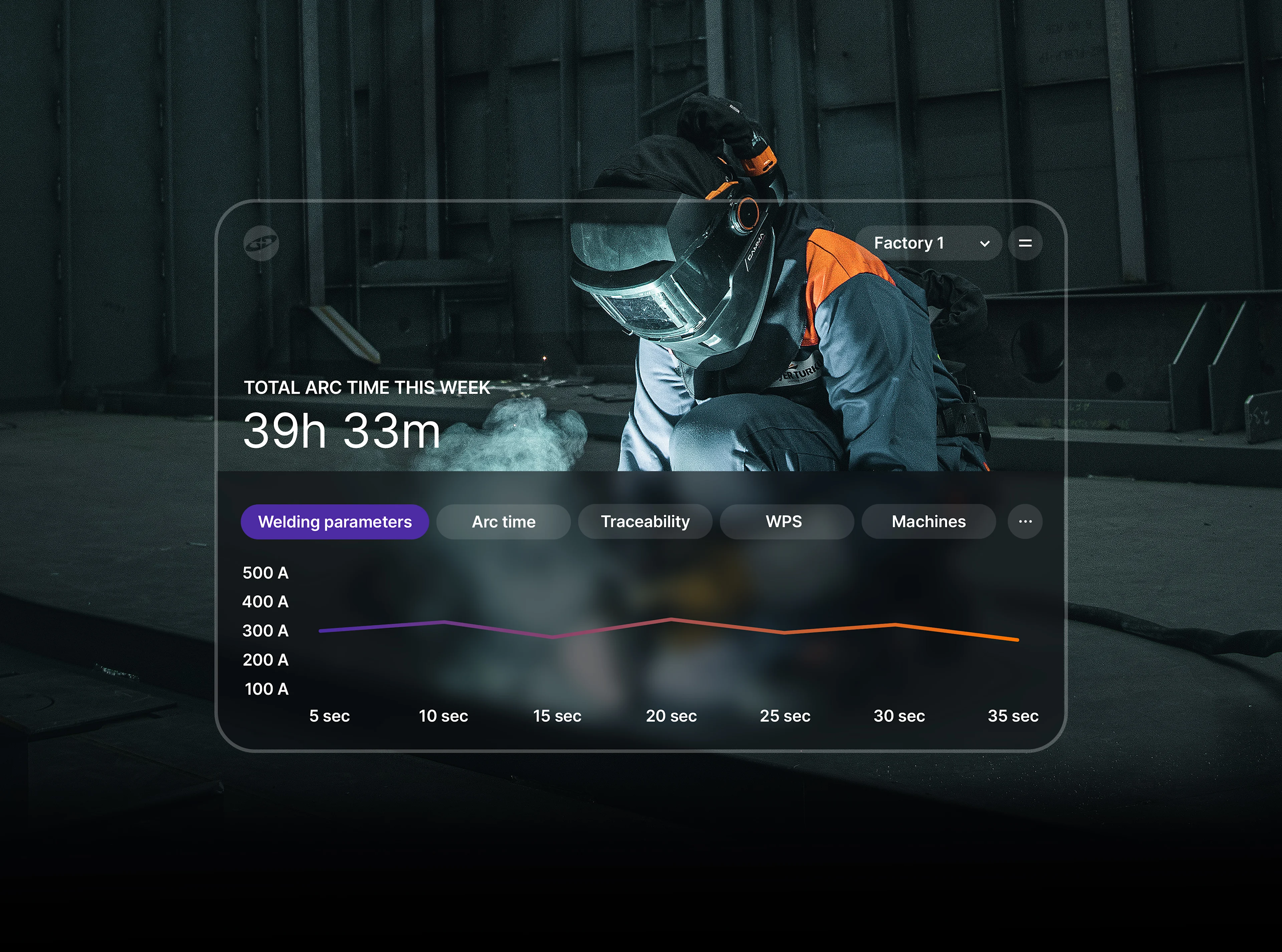

Why WeldEye welding management software?

Knowing your welds is key, but knowing only takes you halfway. Systemizing your knowledge turns it into insight. Analyzing and documenting your insight creates value. WeldEye is built for this exact purpose—to create value for everyone involved in and affected by welding.

Simplification

WeldEye simplifies your welding documentation process and cuts overhead costs.

Control

WeldEye provides full weld traceability and documentation from start to finish, ensuring you are always on top of your welding projects.

Efficiency

WeldEye boosts your efficiency by reducing the need for repair work.

Universal

WeldEye can be used with all welding equipment brands, is available globally, and in multiple languages.

Future-proof

WeldEye is built on cutting-edge technology and IT security, and updates automatically when welding standards are revised.